For ground vibration monitor hard surface installation such as rock, concrete or solid ice, the preferred installation method bolts the standard transducer or the Instantel ground vibration monitor to the surface. A second method, for very low level velocities only, uses a sandbag placed over the ground vibration monitor or standard transducer.

Bolting the Standard Transducer (external geophone)

A standard transducer may be bolted to a surface alone or with the aid of the optional leveling plate.

1) Position the standard transducer with leveling plate, if attached, on the surface and mark the position of the bolt. Use a 3/8 inch (9.5 mm) bolt or threaded rod.

2) Install the bolt according to the manufacturer’s instructions. Slide the standard transducer, and leveling plate, over the bolt. Slide a 3/8 inch (9.5 mm) washer and a 3/8 inch (9.5 mm) lock washer over the bolt.

3) If using the leveling plate, level the standard transducer using the leveling feet and integrated bubble level.

4) Tighten the retaining nut to finish the installation. Press the Test key to check your sensors using Sensorcheck.

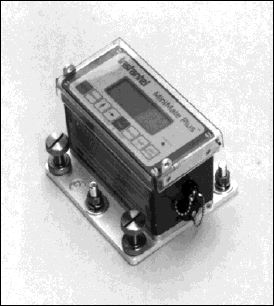

Bolting the MiniMate Plus (internal geophone)

1) Use the optional fastening plate to bolt the ground vibration monitor to a hard surface. The fastening plate has three leveling feet and an integrated bubble level.

2) Attach the leveling plate to the ground vibration monitor with the three screws provided. Use 3/8 inch (9.5 mm) bolts or threaded rods to bolt the ground vibration monitor to a surface. Do not over-tighten the screws when attaching the ground vibration monitor to the leveling plate. Place the unit on the surface and mark the position of the three bolts.

3) Install the bolts according to the manufacturer’s instructions. Slide the ground vibration monitor and fastening plate over the bolts. Slide a 3/8 inch (9.5 mm) washer and a 3/8 inch (9.5 mm) lock washer each bolt.

4) Level the ground vibration monitor using the leveling feet and integrated bubble level. Tighten the retaining nuts to finish the installation. Press the Test key to check your sensors using Sensorcheck.

Sandbagging – For Very Low Velocity Levels Only

Use this method for installations where velocity levels remain very low. The sandbag must be of sufficient size to cover the entire ground vibration monitor or standard transducer and lay on the surrounding surface around the ground vibration monitor or standard transducer. A sandbag should weigh at least 25 pounds (12 kg) containing sand or 1/4” washed gravel. The optional fastening plate or leveling plate can be used with this method. Press the Test key to check your sensors using Sensorcheck. Press the Start Monitor key and place the sandbag over the ground vibration monitor. Except in Manual mode, the Instantel ground vibration monitor delays entering the monitoring mode for five seconds to avoid false triggering caused by placing the sandbag.